I needed to do a little project to keep myself busy over the holidays. So I decided to build a flight simulator.

Motion Mates Prototyping

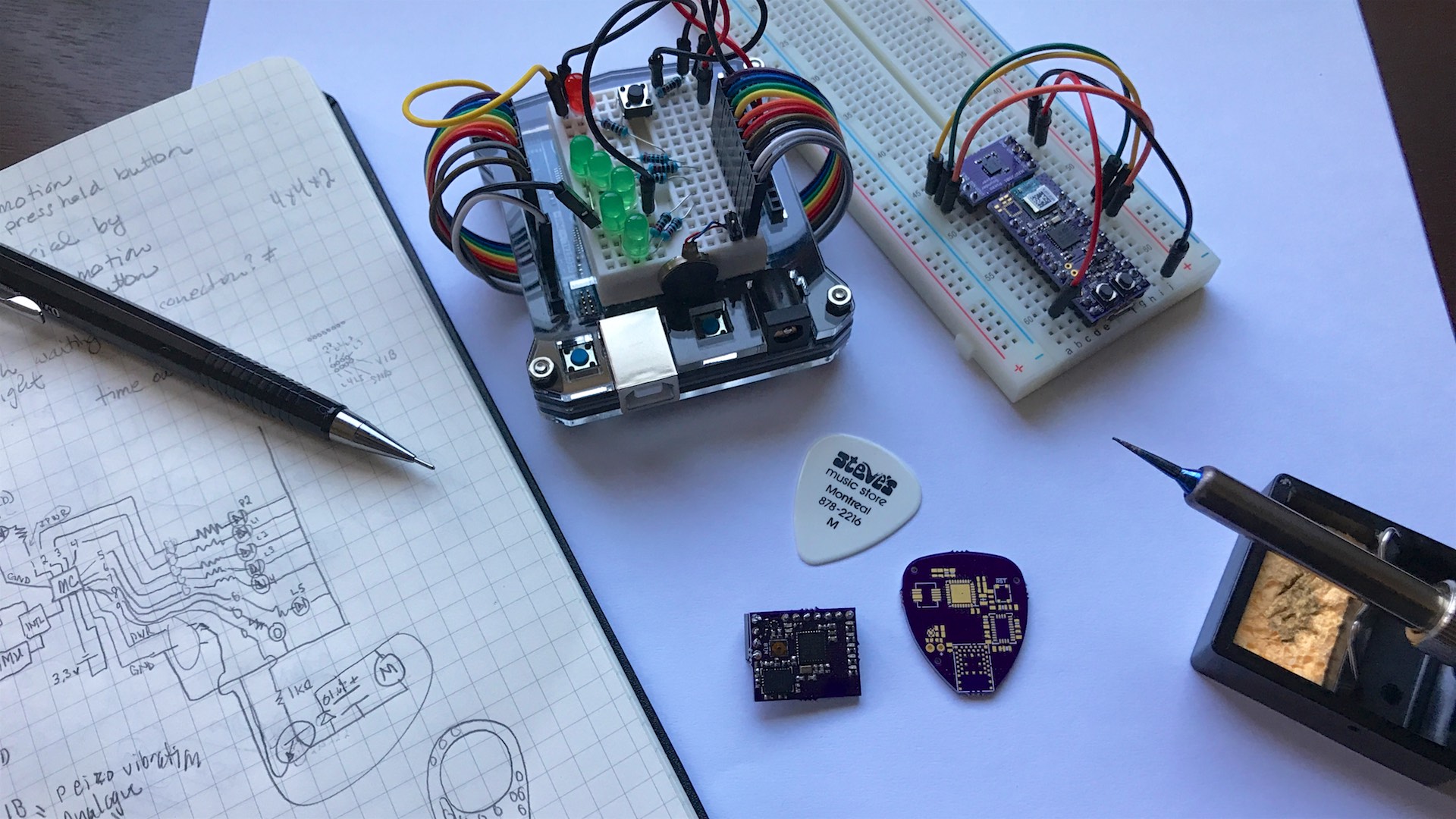

For the last few months I’ve been working on a prototype for my Motion Mates project. The hardware involves a two-part system that can track motion, provide visual/auditory responses, and communicate to an external device over Bluetooth LE. End-users will be able to configure a number of features using the APIs, program it using my supplied SDK/samples for client apps (i.e., an app for an Android phone, iPhone, PC or Apple TV, etc.), or program it directly using embedded code through IDE’s like Arduino. More importantly, this product needs to be small as the current goal is to get everything to fit within the size of a guitar pick. As a mater of fact, the ‘code name’ I’ve assigned to this project is… The Pick !

To get a general idea of what these little guys will do, take a look at the concept brochure.

Anyway, the first boards that came back worked out pretty good. After some tweaking, Module A was completed earlier this month and I’ve just received some PCBs without components in order to start working on the outer casing. The prototype boards are really thick (~1.6 mm), so it will be a bit of a challenge to a make final case when I know the boards can be as thin as 0.3 mm.

Nonetheless, a prototype is still a prototype.

The key thing is to make sure everything is functioning as expected.

Now I’m learning various apps for 3D design and modeling. I’m hoping to have my first mechanical design ready in a few days for printing. The other challenges – or I should say ‘major components of work’ – include the embedded code that goes on the micro controller, the sample code that I will include with the final product, and the packaging. In the meantime I’m waiting on the final boards to come back from fabrication, and toggling between the case design and writing C/C++ sample code for potential customers.

Another important aspect involves creating a social ‘buzz’ around the project. I must admit that coming from an era were there was no internet or cellphones, this last item on the list is perhaps the most difficult, if not the most critical. While I have a very clear concept for all the other parts of the equation, social marketing is one area where I could use a bit of expertise. My long-friend Cathy just relaunched her BusinessSuccess website up in Vancouver, so I’ll be using her resources to help me out. The kind people at Arrow Electronics have also offered to help with marketing and I’ve a few contacts over at Indiegogo that are getting me up to speed in how to successfully launch a crowdfunding campaign tweaked to my specific product – so that’s a good start. After all, even the best product in the world will never be successful if no one knows about it!

Oh… and did I mention the cost to do all this?

Creating a concept and prototyping on an Arduino board is one thing. But when it’s time to miniaturize, create PCBs, optimize code to limit battery drainage, create a small mechanical design that needs to consider the differences between 3D printing and injection molding, package design, looking for packaging and fulfillment companies, etc… everything starts totaling up – both in terms of money and time. The most expensive part to date has been to hire an engineer to help with the development of the prototype. It’s been a learning experience and well worth the cost. Quite a different step from doing insulin iodinations or liquid chromatography in a lab.

Yes. It can be a bit overwhelming at times, but I just need to take it one step at a time.

For now it’s mechanical design. It’s going to be a small but enjoyable challenge to turn my 2D drawings into a 3D fabricated casing that will fit the Motion Mates PCBs in order create that perfect user experience.

More to come at a later date…

This Post Has 0 Comments